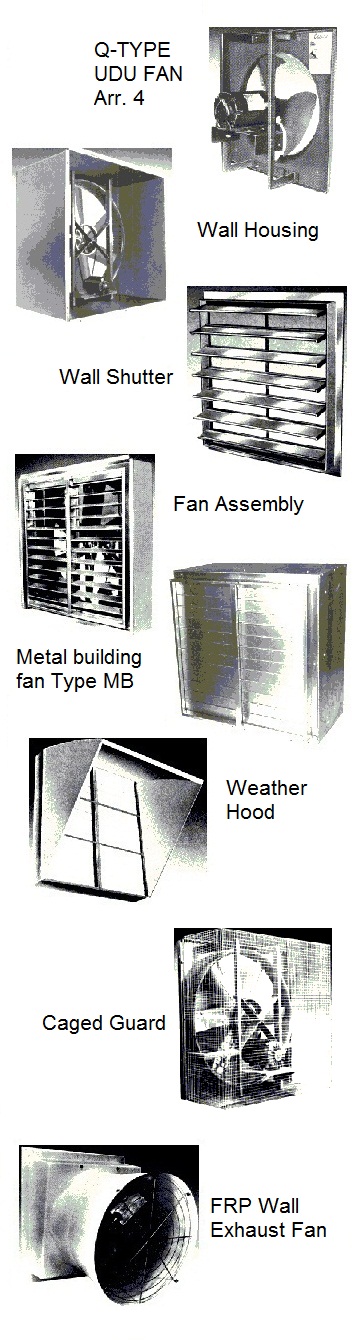

Wall Ventilators (industrial wall propeller panel fans)

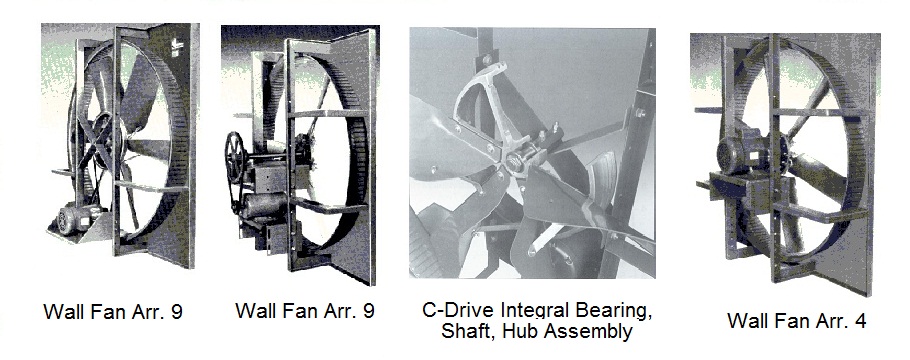

SN, EN, N, CABL, CABH, CBL, CBH, CBHX, CBC, LCBC, CDC, C-AL, UD, CUD, UDU, UDP, PT, MB, XB, SXB, HV, HVA, ADD, DDP, DDS, X, AX, P, SD, XF, UF, PV, PT fans: axial flow through fan panel fans designed for low pressure building ventilation, room ventilation, industrial ventilation, commercial ventilation and industrial process application. Ventilators applications include heat, smoke, and fume removal; process ventilation and process air handling; process drying with ambient or preheated air; comfort process cooling and general ventilation of buildngs. Available in direct drive fan arrangement 4 and corresponding belt drive arrangement 9. Ventilator sizes from 6 to 84. Capacities: to 350,000 CFM. Fan static pressure to 1.5 inches water gauge.

Spark Resistant X-proof ventilator construction: wall fan for non-sparking x-proof applications is supplied in AMCA A (all aluminum or monel airsteram), AMCA B (aluminum wheel, or monel wheel), or AMCA C (buffer type) spark resistant fan construction. For AMCA A applications wheel is made of non-ferous material with monel shaft and special x-proof motor.

High temperature ventilator construction: wall fan is avaialble in high temeparture construction with high temperature motor and steel wheel, or stainless steel fan propeller.

Corrosion resistant construction and chemical duty construction: for corrosive environment wall fans are avaialble in 304 SS, 316 SS, or 316 L stainless steel construction. For chemical process applications wall fans are available in fiber reinforced plastic frp construction, or in polypropylene blower construction, or in plastic.

Wall fan accessories: wall housing, wall cabinet, heavy gauge housing, extended wall housing, wall housing access door, inlet guard, outlet guard, caged guard, fixed louver, shutter, manual shutter with pull chain and quadrant lock, gravity automatic shutter, motorized shutter, back draft damper, shutter motor, BELIMO motor, NEP motor, Multiproducts motor, Delay switch, Speed controller, VFD, intake hood, discharge hood, weather hood, hood bird guard, hood bird screen, insect screen.

Controls and drives: pressure switch, end switch,

electrical damper motor, delay switch, pneumatic actuator, speed

control, vfd control, motor starter, carbon monoxide sensor, oxygen

sensor, electronic gas sensors and others.

Call us today: 1-888-763-1800 E-mail: nis@primus.ca