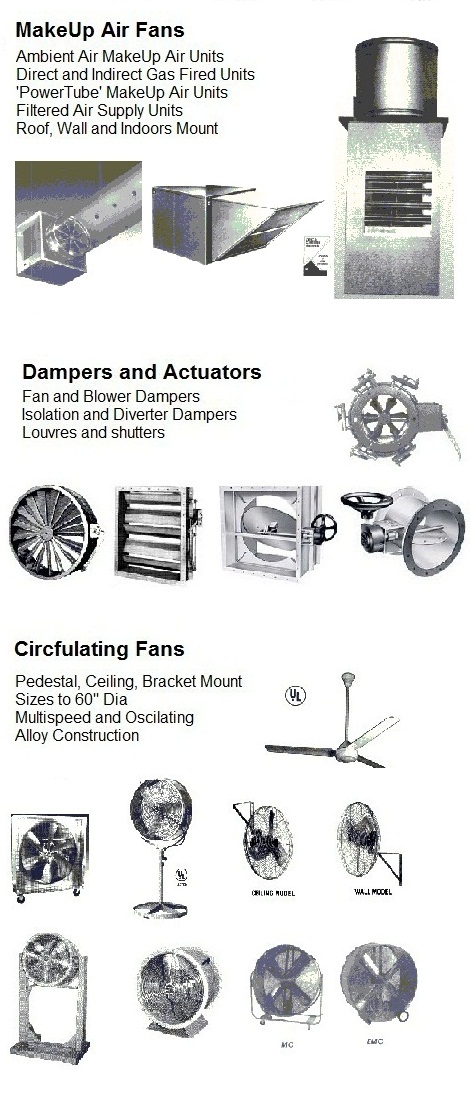

In many areas,

air must be conditioned before entering a facility. This necessitates

that the make-up air system have heating and often air cooling and

filtering abilities. A so called make-up air unit is required.

Typically a make-up air system includes an air mover section, usually a

propeller or centrifugal type fan, an air tempering section containing

heating and where necessary cooling and filtering equipment, and a

control system.

Fan selection

and power requirements are generally determined by the application.

When only general ventilation is required (fan pressure requirements

are low), a propeller type fan can be utilized. To supply make up air

through a duct system with a resistance of 0.5 in w.g. or more, a

centrifugal fan should be considered. In either system, diffusers may

be used to direct the discharge air velocity.

In situations

where the inside air quality is acceptable, often a portion of the

inside air may be drawn back through the make-up air unit where it is

recirculated back into the building. Advantages of using Canada Blower

Recirculating Make-Up Air fan units are lowered heating costs, better

indoor air mixing (reduced air stratification), as well as constant

building pressurization.

An adequate amount of makeup air is required for personnel, machines,

and processes to operate properly, efficiently, and safely. Failure to

provide adequate make-up air is often the cause of unnecessary

expenditures for additional exhaust systems and heating or cooling

equipment. These devices in turn compound the problem of air starvation

within the building. Reliable, cost effective equipment is available

from Canada Blower to supply the make-up air necessary to balance air

removed from a structure.