CANADA BLOWER FANS AND VENTILATORS

Centrifugal fans

Axial fans

Custom Fans

Dust Collectors

Hi-temp fans

Fume exhausters

Air Knives

Heating coils

Cooling coils

Regenerative blowers

Expansion joints

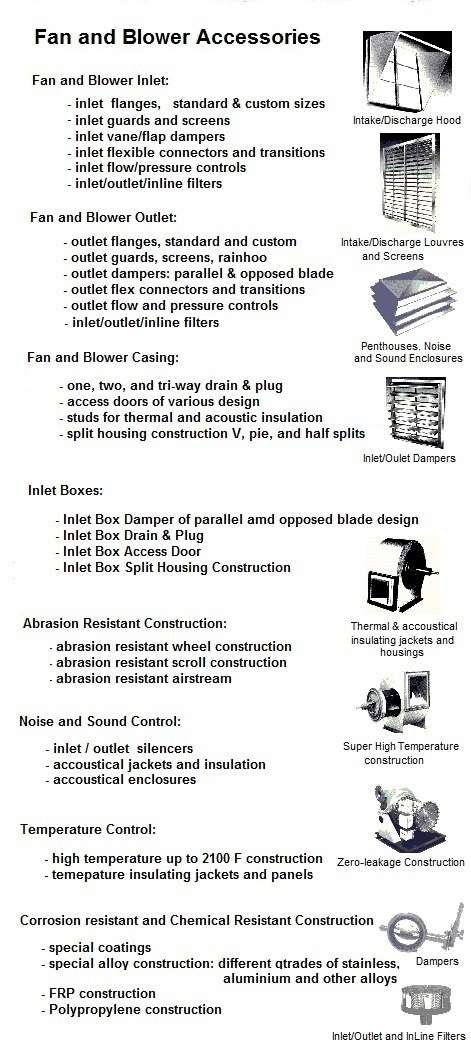

Dampers

Flexible Duct

Stainless Steel duct

Aluminum Duct

Systems installation

Louvers

Ventilation Systems

Fiberglass fans

Plastic Fans

Aluminum fans

Stainless steel fans

Steel fans

Filters

Filter systems

Inlet Silencers

Exhaust Silencers

Multi-stage blowers

Vacuum pumps

Personnel cleaning systems

Industrial curtains

Replacement fan / blower parts

Call us today: 1-888-763-1800 E-mail: nis@primus.ca