American Coolair / ILG Fans

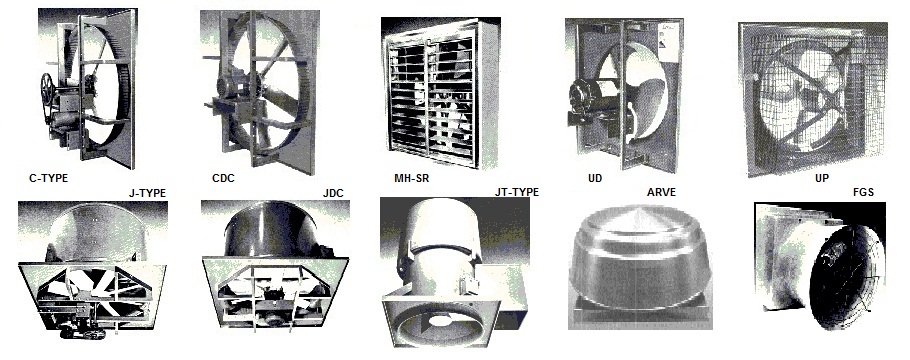

J, JBH, JBHX, JBC, JDC, JT, JTBC, JTEBC, JTDC, HS, HSE:

upblast power roof ventilators. Fan sizes: 18 to 84. Capacity: up to

105,000 CFM. Pressure: up to 2.5 inches of water gauge. Accessories:

safety disconnect switch, pre-fabricated roof curb, magnetic latches,

galvanized damper doors, automated heat and smoke

venting, spark resistant construction, protective coatings, inlet and

outlet

guard, duct connector, disconnect switch, safety chain.

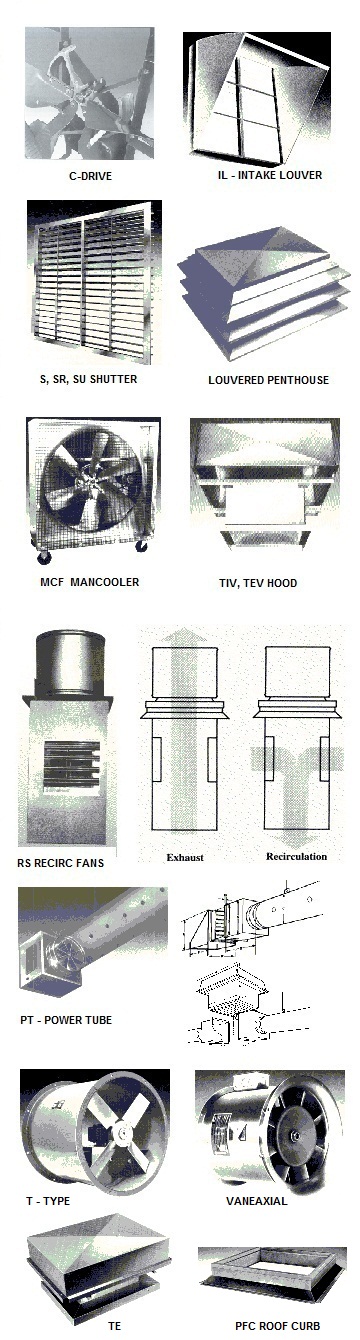

CABL, CABH, CBL, CBH, CBHX, CBC, CDC, C-AL, UD, UDU, UDP,

MB: wall propeller fans for exhaust and supply applications. Fan

sizes:

6 to 84. Capacity: up to 110,000 CFM. Pressure: up to 2.5 inches WG.

Ventilator accessories: WH wall housing, WS wall sleeve, MC mounting

collar, S

wall shutter, SR reinforced wall fan shutter, LRW shutter, SU shutter,

shutter motor kit, delay switch, manual shutter kit, bird guard,

gravity shutter, IL intake louver, IH intake hood, EH exhaust hood, SG

safety guard cage, disconnect switch, speed controller, controls.

PT Fan: power tube fan make-up air systems. Sizes: 18 to 48 inches. Fan capacity: up to 30,000 CFM. Pressure: up to 2 inches of water gauge. Accessories: gravity shutter, motorized back draft damper, wall flange, face damper, bypass damper, spark resistant construction, power ventilating tube, face and bypass damper, speed controller, controls.

PB, PBC, PEB, PEBC, PD, PDC, PED, PEDC, PSB, PSB-F, PSD, PSD-F, RPB, RPBC, RPD, RPDC, RE, REBC, REDC, RES, RESBC, RESDC, PUD, PEUD, PSUD Fans: hooded power roof ventilators in exhuast or supply configuration, or reverse flow option. Ventilator sizes: 12 to 84. Fan capacity: to 105,000 CFM. Pressure: up to 1 inch. Accessories: backdraft damper, bird screen, safety disconnect switch, roof curb, spark resitant construction, filters, filter gauge, protective coatings, fiberglass insulation, reversing switch, controls.

T, TBC, TEBC, TD, TDC, VA, VAB fans: duct tubeaxial

fans and

vaneaxial fans. Sizes: 6 to 84. Capacity: up to 105,000 CFM. Ventilator

accessories: mount feet, duct adaptors, inlet/outlet guard,

inlet/outlet bell, motor cover, belt guard, mount bracket, baryfol pad,

speed controller, controls.

CFS & SIS fans:

Canada Blower CFS & SIS Centrifugal Filtered supply fans with

four-side and on-side inlets are designed for roof mounting on curbs to

provide make-up filtered air to general ventilation systems.

Applications include ventilating of a variety of commercial and

industrial facilities.

The fan has a double-width double-inlet centrifugal wheel with forward

curved blades. The fan filters are 1" cleanable aluminum mesh. Housings

of Canada Blower CFS & SIS roof ventilators are constructed from

mill galvanized steel. The fans capacities: up to 10,000 CFM / to 1.5"

WG static pressure. Fans of this type are quite efficient, dependable

and require relatively little maintenance.

Access to the fan motor, drive and filters is accomplished by removal

of the top utilizing (4) zinc coated, quick release snap latches.

Canada Blower CFS / SIS power roof ventilators have a V-belt drive with

ajustable motor pulley, as well as adjustable motor support. All Canada

Blower roof exhaust fans are available with such accessories as

backdraft and motorized dampers, roof curbs, protective coatings,

safety guards, disconnect switches, and many other useful features.

TEV, TIV, LVX, LVN ventilators: gravity ventilators and louvered penthouse fans. Custom sizes. Accessories: gravity automatic damper shutter, motorized damper, roof curb.

MCD, MC: air circulators, spot coolers, booster fans and mancoolers. Sizes 12 to 48.

Custom coatings and finishes. Alloy blower construction.

High

temeparature fan construction.

Call us today: 1-888-763-1800 E-mail:fan@cogeco.net