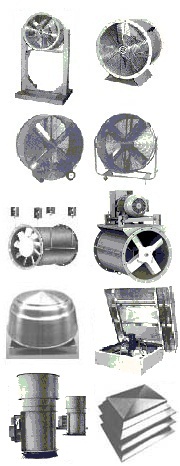

AXIAL FLOW FANS

Our Axial fans are found

throughout

the world operating in industrial processes where performance,

reliability

and maintainability are of paramount importance. Ranging in diameter

from

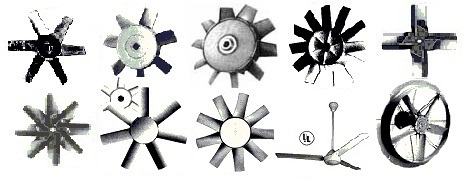

6 inches to over 9.3 m, and with a variety of impeller designs, control

systems

and fan layout options, they form a comprehensive series of axial fans

to

satisfy virtually all industrial applications. The majority of the fans

we

supply can be grouped into four broad categories; variable pitch, non

variable

pitch, and mixed flow. All are supplied to the same exacting standards.

A variable pitch balde in axial

fan blower is used where precise control of static pressure within

supply ducts is required. The fan wheel will spin at a constant RPM .

The blades follow the control pitch hub. As the hub moves toward the

rotor the blades increase their angle of attack and an increase in flow

results.

Axial flow ventilators have blades that force air to move along the

shaft about which the blades rotate. Axial fans blow air across the

axis of the fan, linearly, hence their name. This type of fan is used

in a wide variety of applications, ranging from small cooling fans for

electronics to the giant fans used in wind tunnels.

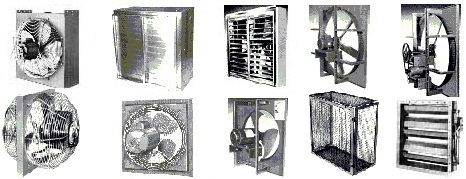

We offer a complete line of propeller fans, capable of moving from a few hundred cubic feet per minute, to heavy duty adjustable pitch props with capacities up to 1,000,000 CFM and with static pressures from 0 " Water Gauge (WG) to 15 " WG.

Our fans include standard axial fan designs as well as custom manufactured ventilator units to meet customers' requirements based on ISO 9001 manufacturing standard.

Over the years we supplied axial fans to a wide range of industries and for various applications including: general building ventilation fans, make-up air systems, tunnel ventilation blowers, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC ventilators, paint / spray booth fans, fertilizer and various emission control applications, axial fans for corrosive applications made of FRP, stainelss steel, or anodized aluminium. For warehouse and production we offer a complete line of manecoolers, spot coolers, and ceiling fans. For the commercial HVAC market, we offer general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant design, variety of coatings and accessories are available to meet practically any application needs.

Our air moving ventilator products are best know for "industrial quality" assuring reliable performance, relentless dependability and longevity. A staff of specially trained engineers will design a dependable fan that exactly fits customers' dimensional and performance requirements.

Canada Blower fans and blowers are sold and serviced by air moving experts that can evaluate your needs and provide best recommendations for your application.