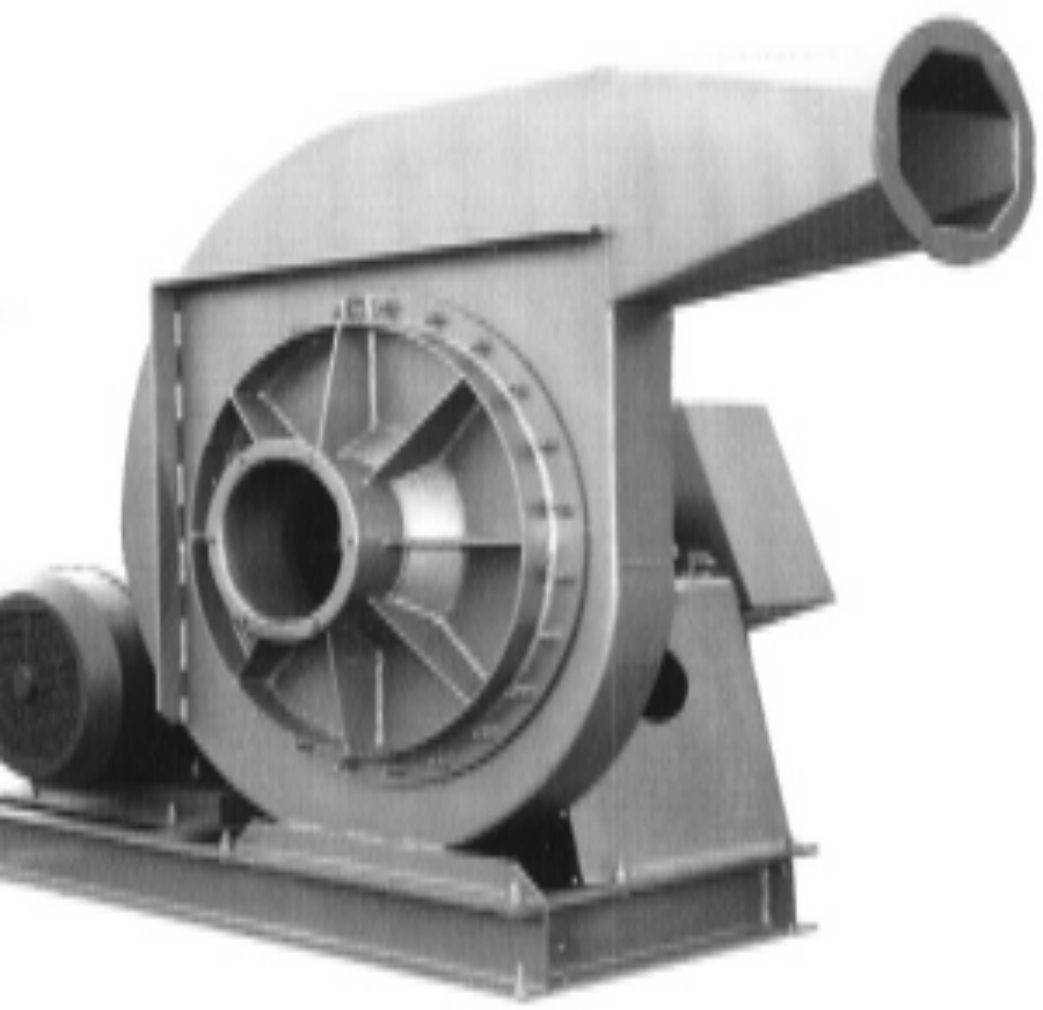

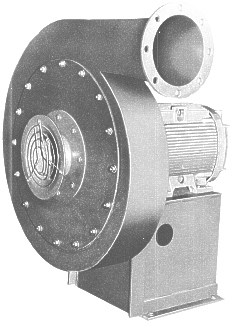

Industrial High

Pressure Blowers

PB, HPPB, CB, E, R, RE blowers : industrial pressure blowers and high pressure blowers supplied in cast aluminum, cast iron, or all-welded fan construction to prevent flexing at high pressure. Available in direct drive arrangements 4/4V/4H/7/8 and belt drive blower arrangements 1/9/10. Capacities: to 10,000 CFM. Single stage pressure blowers develop up to 4 psi static pressure. Two stage pressure blowers and multistage pressure blowers are for higher pressure.

Aluminum wheel, Steel wheel, or Alloy blower wheel: industrial pressure blower and high pressure blower wheels are of riveted, cast, or all welded construction. Flat wheel, tapered wheel, and dual tapered blower wheel design. Available with RBO radial self-cleaning blades; RTS radial tip blades; BI backward inclined blades, or BC backward curved non-overloading blower blades. Alloy fan wheels are available in SS 316L, SS 304, SS 204, monel, corten, FRP, and abrasion resistant construction. The blower pressure curve remains stable from wide open to closed off position without pulsation on all blower wheel designs.

Inlet flanges, outlet flanges, companion flanges: continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern.

Shaft seals, low leakage, zero leakage, gas tight, airtight blower construction: shafting is straightened to close tolerance to minimize "run-out" and ensure smooth operation. Ceramic shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing, gas-purgeable, double carbon ring shaft seal, gas-tight, or airtight construction, and zero-leakage blower construction.

Heat fan construction up to 700 F: includes high temperature paint, shaft cooler, shaft-cooler guard, steel, or alloy wheel.

Cladding for sound attenuation and silencers: cladding consists of 2 inches mineral-wool insulation covered with a welded steel jacket. Acoustic cloth jackets. Inlet silencers/outlet silencers supplied with matching flanges, or inlet/outlet venturi with guard, or plain pipe connection.

Inlet filter assemblies: cartridge type, with polyester element / wire mesh oil wetted element / high flow synthetic element / paper element. Available with protective hood, or hood-silencer.

Standard fan accessories:flash / raised access door, inspection port, drain and plug, unitary base, shaft and bearing guard, belt guard, motor cover, spring vibration isolation, rubber-in-share (RIS) vibration isolation, vibrating pads, wafer style / lug style outlet damper and electrical / pneumatic actuators.

Controls and drives: variable frequency drives (VFD),

across-the-line starters, RTDs, pressure sensors, flowmeters - complete

control packages in

NEMA 1, NEMA 3R, NEMA 4 enclosure. Expansion Joints, Flexible

Connectors and Compression Couplings isolate Multistage Blower to allow

for thermal expansion and mis-alignment of piping. Pressure / Vacuum

Relief Safety Valves are of spring loaded type type, or weight type.

They set-up point of operation and bleed-off to prevent

over-pressurization, or relief vacuum.

Inline Check Valves direct airflow or vacuum in one direction only.

Pressure/Vacuum Controls include differential pressure gauge up to 15

PSIG, vacuum gauge from 30” to 0” Hg, temperature gauge, gauge snubber

to reduce pressure pulsation, and .25” pet-cock valve to isolate the

gauge.

Blower Silencers are offered as inlet and discharge silencers with

sound absorbing elements. Sound Enclosures are custom made based on

application requirements.

Inlet Filters are offered with wire-mesh oil wetted (multi-wash), high

efficiency ultra-synthetic (polyester, washable), or paper (thrown

away)media. Controls included Differential Filter Pressure Gauge used

as Filter Restriction Indicator. Filter casing is available as open

flange design, hooded design, or combined filter-silencer assembly.

In-line filters are custom.