Centrifugal Fans manufactured by experts !

Vent Fan Sets with Forward curved wheel blades are designed for air handling purposes only, where there is a need to move high volume of air at medium pressures. They are availble as Junior sets in direct drive Arrangement 4 and belt drive Arrangement 10 ventilator configurations.Canadian Blower Company offers a complete line of centrifugal fan equipment, from small Baby Vent Sets capable of moving a few cubic feet per minute (CFM), to large, heavy-duty industrial mechanical draft fans with capacities to 1,000,000 CFM and with static pressures from 0" Water Gauge (WG) to 150" WG.

Canadian Blower is a leading supplier of industrial and commercial fans, ventilators, blowers and accessories for various air-moving applications.

Canadian Blower Co. products include standard centrifugal fan and customized blowers designed to meet our customers' requirements based on Canadian Blower manufacturing standard.

Over the years Buffalo Fan / Canada supplied centrifugal fans to a wide range of industries and applications including: combustion air supply, material handling, process ventilation, ovens and dryers, iron and steel industry, mine and tunnel ventilation, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC, paint/spray booths, fertilizer and various emission control applications. For the commercial HVAC market, Buffalo Fan offers general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant design, variety of coatings and accessories are available to meet practically any application needs.

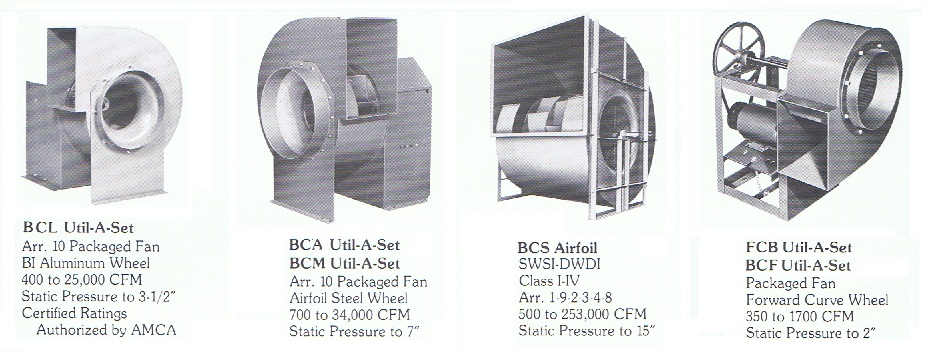

Centrifugal Fan Utility Sets, are ideal for ventilation of commercial and institutional buildings, where medium to high pressure is required. Vent sets are available in Class 1, Class 2, or Class 3 construction for low, medium and high pressure blower applications. Fan features non-overloading centrifugal wheel, available in backward inclined, backward curved, or backward curved hollow airfoil designs. Fan construction includes inlet cone with venturi profile, blower wheel, heavy duty shaft, heavy duty pillow block bearings, shaft and bearing pedestal, rotatable scroll housing in CW, or CCW rotation, adjustable motor base, and weather motor cover. Flanged Inlet, Flanged Outlet, Companion flanges, Access Door, Drain, Plug, Inlet Screen, Outlet Guard, Inlet Vane Damper (external, or internal design), Outlet Damper, Damper Motor, Outlet Shutter, Spark Resistant Construction, High temperature construction up to 650 F, Silencers, Acoustical Jackets, Spring vibration isolators, Rubber-in-share vibration isolators, vibration insulation pads, vibration rails, UL 705, and UL 762 labes are optional accessories avaialble on all fans. All designs utilize standard V-belt drive supplied in fixed pitch, or variable pitch option. Motors are of ODP, TEFC, or X-proof enclosure, available with standard, or high efficiency VFD duty versions. Special ventilator motors are available on spa. Stainless steel, aluminum, or special coatings, as eisenheiss, heresite, acrylic epoxy, backed enamel and others are avaialble upon request.

Double Width Double Inlet Centrifugal Fans are designed for air handling applications. They are available in Class 1, Class 2, or Class 3 construction for low, medium and high pressure applications. Fan features a non-overloading DWDI centrifugal fan wheel, available in backward inclined, backward curved, or backward curved hollow airfoil designs. Fan construction includes inlet cones with venturi profile, DWDI blower wheel, heavy duty shaft, heavy duty pillow block bearings, rotatable scroll housing in CW, or CCW rotation, unitary base with adjustable motor base, and belt guard. Typically it is supplied in Arrangement 3 construction. Inlet Flanges, Outlet Flange, Companion Flanges, Access Door, Drain, Plug, Inlet Screens, Outlet Guard, Inlet Vane Dampers (external, or internal design), Outlet Damper, Damper Motor, Outlet Shutter, Spark Resistant Construction, Silencers, Acoustical Jackets, Spring vibration isolators, Rubber-in-share vibration isolators, vibration insulation pads, are optional accessories. All designs utilize standard V-belt drive supplied in fixed pitch, or variable pitch option. Motors are of ODP, TEFC, or X-proof enclosure, available with standard, or high efficiency VFD duty versions. Special motors are available on spa. Stainless steel, aluminum, or special coatings, as eisenheiss, heresite, acrylic epoxy, backed enamel and others are avaialble upon request.