Air Curtain Fan Blowers made

in

New York

Air Curtains provide a

controlled

stream of air across a building entrance or doorway to separate

interior

atmosphere from exterior environment. Air curtain’s airstream prevents

cold,

hot, or humid outdoor air, as well as insects and dust, from

infiltrating

the inside the building. This is why Air Curtains are considered as the

first

line of defense for employee safety.

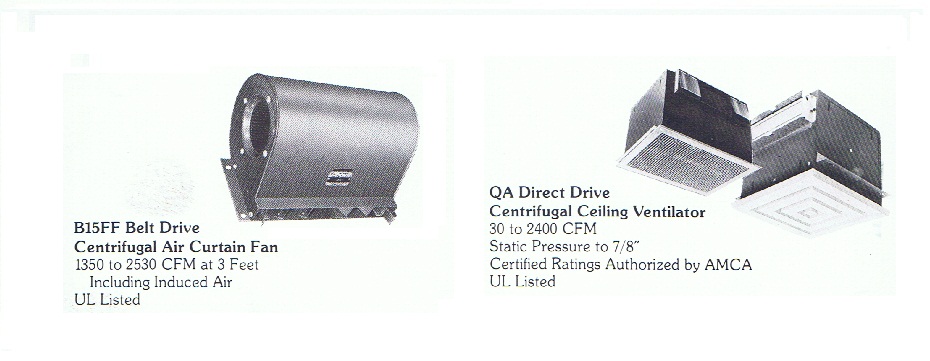

Air Curtain Construction typically an air curtain will incorporate double width blower, belt, or direct driven, heating / cooling coils, or a gas fired coil, electrical controls, such as door plunger switch, speed controller, disconnect switch, and others, and mounting accessories, such as mounting brakets for suspended, or verhead mount.

Although air curtains require power to run the blowers and heaters, Air Curtains save much more costs by reducing drive-thru time, window wind fume hazard, providing low-first cost and low total cost as well as additional energy savings in energy battle.

Design Consdierations: To properly design an air curtain application the airstream must hit the floor with enough velocity to create a stable split right at the doorway. Design criteria for selection of proper air curtain for a given application include height and width of the door opening, intended usage, required characteristics of the airflow, which are combination of velocity, volume, and uniformity and the proper balance between each.

Once an air curtain is activated, it creates a split which uses the internal pressure to resist infiltration of temperature, rain, wind, debris, insects, etc. among the conditioned indoors and unconditioned outdoors air.

Typical applications include various Commercial entrances, loading doors, hotels, hospitals, stores, public facilities, and other commercial buildings, and other applications, such as Food service, where all aluminum, or all stainless steel air curtains are utilized .

While air curtains have been

commonly

used for decades to separate environments in the workplace, perhaps now

is

the time safety professionals should consider them to help eliminate

industrial/commercial

doorway accidents as well as keep restaurant drive-thru employees safe

from

CO poisoning and wintertime temperature extremes.

Air curtains cut cold air loss

and reduce humidity, thus reducing the load on refrigeration or

air-conditioning plant and thereby saving energy by reducing compressor

running time, maintenance, gas and recharging intervals. These units

are an alternative to fast-acting roller doors and

PVC slat curtains, and can be situated above or to the side of

industrial doorways to create a powerful seal across the opening,

keeping cold air in while providing complete visibility and access.

This means that forklift drivers don't have to get out of their cabs to

open and close doors so that moving from one area to another is a lot

easier and productive. Unlike plastic slat curtains, which quickly

become opaque with use, an air curtain provides 100% visibility at all

times. Units have been installed in loading bays, factories, hangars

and production facilities, such as food processing and pharmaceuticals,

where differential temperatures are encountered overseas.

Air Curtains are supplied with optional easy mounting trim key.

All models AIR-CURTAINs

bear

the AMCA Certified Ratings Seal.

Call us today: 1-888-763-1800 E-mail: fan@cogeco.net