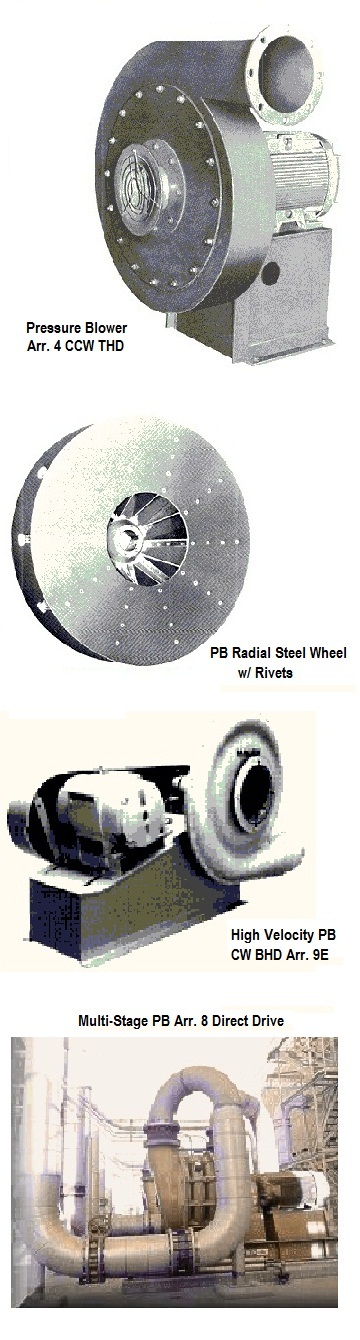

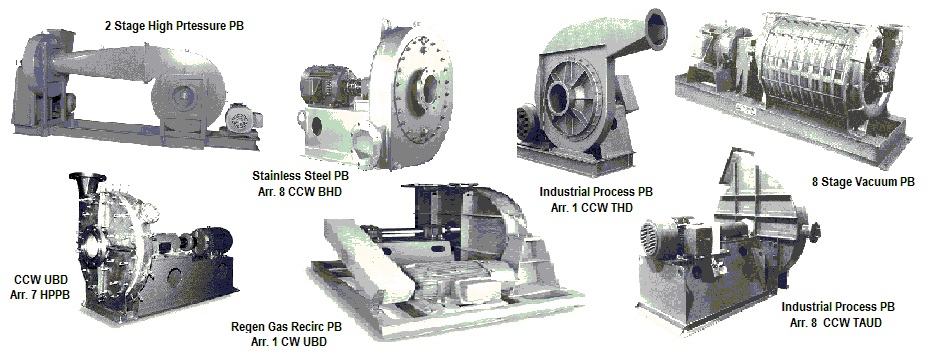

Multistage Blowers deliver up to 150,000 SCFM of uncontaminated gas flow at up to 30 PSIG pressure, and from 20” to 0” Hg vacuum. Typical multi stage blower applications include air conveying, industrial & municipal water waste, water aeration, petroleum and chemical refineries, flotation, central vacuum systems, cell aeration, sulfur recovery, fluidized bed units, gas boosters for carbon dioxide, nitrogen, propane, natural gas, steam compressors for vapor recompression systems, electroplating, agitation of tanks, cement pneumatic conveying, landfill gas recovery, leaching process, soil remediation, paper transport, scrap collection, powder recovery, and all applications requiring medium pressure, or vacuum at relatively large volume of flow.

Multistage Pressure Blowers are available with cast iron, or fabricated steel casing enclosing cast aluminum, fabricated aluminum, or stainless steel rotors. ANSI 125/150 flange connections, as well as metric standard flange connections are standard. Shaft sealing is provided by labyrinth seal, mechanical seal, purgeable nitrogen, or other gas seal, gas tight seal, or by sealed bearing compartments.

Multi-stage Pressure Blower Packages are supplied on unitary base of standard or isolation type with RIS, or spring vibration isolators. Power transmission is implemented by V-Belt Drives complete with V-belts, adjustable or constant speed sheaves and pulleys, bushings, and motor slide bases; or by direct drive coupling. Motors are of High Efficiency design. OSHA Belt Guard and OSHA Coupling Guard are standard.

Expansion Joints, Flexible Connectors and Compression Couplings isolate Multistage Blower to allow for thermal expansion and mis-alignment of piping.

Pressure / Vacuum Relief Safety Valves are of spring loaded type type, or weight type. They set-up point of operation and bleed-off to prevent over-pressurization, or relief vacuum.

Inline Check Valves direct airflow or vacuum in one direction only.

Pressure / Vacuum Controls include differential pressure gauge up to 15 PSIG, vacuum gauge from 30” to 0” Hg, temperature gauge, gauge snubber to reduce blower pressure pulsation, and .25” pet-cock valve to isolate the gauge.

Blower Silencers are offered as inlet and discharge silencers with sound absorbing elements. Sound Enclosures are custom made based on application requirements.

Pressure Blower Inlet Filters are offered with wire-mesh oil wetted (multi-wash), high efficiency ultra-synthetic (polyester, washable), or paper (thrown away)media. Controls included Differential Filter Pressure Gauge used as Filter Restriction Indicator. Filter casing is available as open flange design, hooded design, or combined filter-silencer assembly. In-line filters are custom.

Controls and drives: variable frequency drives (VFD), motor starters, are available in NEMA 1, NEMA 3R, NEMA 4 enclosure, as well as for x-proof blower applications.

Call us today: 1-888-763-1800 E-mail: fan@cogeco.net

Pressure

blowers for air-knife blowoff systems:

- Heavy-duty high-pressure air-knife blowers for tough industrial

process applications;

- Blow-off blowers, process cooling, conveyor cleaning fans, process

blowers;

- Pressures to 10 PSIG, velocities to 40,000 Ft/min, air volumes to

10,000 CFM;

- Adjustable volume & pressure systems;

- Variety of blower types available - centrifugal pressure blowers,

regenerative, rotary-lobe, multistage... depending on pressure required;

- Aluminum, steel, stainless stell, plastic blower options, variety of

styles and sizes.

OTHER BLOWERS AND FANS WE SUPPLY:

- Combustion air supply blowers;

- Oven circulation fans;

- Pneumatic conveying blowers;

- Dust collector fans;

- Super high temperature fans;

- Material handling blowers;

- Exhaust and supply process fans.

Canada Blower OEM fans are specifically engineered and efficiently manufactured to meet the specific needs of individual OEM requirements.

Canada Blower manufactures industrial duty high temp fans for operating temperatures up to 2200°F. Canada Blower Fans has been in business for 4 decades, and has supplied thousands of fans to furnace manufacturers worldwide. Daniels Fans users air cooled shaft and bearings to eliminate costly and troublesome water cooling.

Canada Blower provides service and replacements for these original fan manufacturers:

Aerovent

American Blower

American Davidson

American Standard

Buffalo Forge

Canadian Blower and Forge

Clarage

Green

Howden Brown Boveri

Howden Canada

Howden Parsons

James Howden

Joy

KKK Fans

Novenco

Novenco Canada

SMC

Sheldon

Sirocco

Stork

Sturtevant

Taurus

Tellus

Twin City Fan

Uranus

VSH

Variax

Westinghouse

Canada

Blower general purporse compact direct driven forward curved blowers:

- 8 sizes from 1/60 HP to 1.5

HP, from 20 to 1,000 CFM, up to 2" WG pressure;

- steel forward curved fan

wheels with welded steel housings and industrial grade finish;

- designed for use as air

replacement and air make-up in permanent istallations;

- can be used in duct

installations for low-noise air moving applications;

- thermal overload protection,

speed controllable;

- different fan discharge

positions are available.

OTHER BLOWERS WE SUPPLY:

Canada Blower Regenerative

Blowers

- Performances to 800 CFM @ 10

PSIG;

- Motorless models for belt

drive fan applications;

- 2-Stage side chanel blowers

for higher pressures.

Canada Blower Multistage

Blowers

- Centrifugal multi-stage

blowers for high volume & high pressure applications;

- Air volumes to 20,000 CFM,

pressures to 35 PSIG;

- Up to 10 individual blower

stages.

Blowers in Series

- Super high pressure

regenerative and rotary lobe blowers in series;

- High volume centrifugal

blowers in series for higher CFMs;

- HIgh temperature together

with high pressure fan applications.

Canada Blower Rotary Lobe PD

Blowers

- Up to 3,000 CFM @ 15 PSIG in

single stage;

- 2-stage models for up to 25

PSIG pressure;

- High temperature blower

models with heat exchangers between stages.

Industrial & OEM

Centrifugal & Axial Fans & Blowers

- Up to 200,000 CFM to 4 PSIG

pressure, to 1000 F operating temperature;

- Abrasion resistant,

explossion proof, fiberglass & stainless steel ventilator models;

- Material handling fans;

combustion pressure blowers .

Canada Blower High Temperature

Fans

- Super high temperature (to

2,000 F) centrifugal and axial fans & blowers;

- Oven plug fans and air-kits;

- High temperature and high

pressure radial blowers.