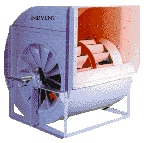

Industrial backward curved fans and blowers

SWSI, DWDI, AcF, PLR, BI, BC, AF, ST, Backward Inclined

Blowers, Aerocline fans, General Purpose, GP, BL, Limit Load, LL,

Buffalo Vent Set, BCV, BCA, BCM, BCS: industrial backward curved

blowers are supplied in

welded heavy gauge steel construction to prevent flexing at high

pressure.

Available in direct drive blower arrangements 4/4V/4H/7/8 and belt

drive

arrangements 1/3/9/10. Arr. 10 blowers are known as ventilating sets

(vent

sets). Available in single width single inlet (SWSI), or double width

double

inlet (DWDI) fans. Blower capacities: to 500,000 CFM. Static pressure

up

to 100 inches water gauge depending on the class of construction.

Typical

fan class of construction is Class 1, 2, 3, 4, 5.

In centrifugal fan, as opposed to axial flow fan, the air is

moving perpendicularly to the fan shaft. Often called a "squirrel cage"

(due to its similarity in appearance to exercise wheels for pet

rodents), the centrifugal fan has a moving component (called an

impeller) that consists of a central shaft about which a set of blades,

or ribs, are positioned. Centrifugal fans blow air at right angles to

the intake of the fan, and spin the air outwards to the outlet (by

deflection and centrifugal force). The impeller rotates, causing air to

enter the fan near the shaft and move perpendicularly from the shaft to

the opening in the scroll-shaped fan casing. A centrifugal fan produces

more pressure for a given air volume, and is used where this is

desirable such as in leaf blowers, hair driers, air mattress inflators,

inflatable structures, and various industrial purposes. They are

typically noisier than comparable axial fans.

Canadian Blower's SQB backward inclined wheel and square

housing design, the SQB is efficient, economical and versatile. It is

also quickly available through Buffalo Fan's Stock Fan program.

Packaged fans, those furnished with motor, V-belt drive, belt guard and

other options, are factory aligned, run tested and shipped ready to

install. By eliminating jobsite assembly, the packaged SQB fan can

substantially reduce overall installation cost.

Aluminum blower wheel, Steel wheel, or Alloy wheel: industrial backward curved (bc) blowers and fans are supplied with aluminum wheel or corten wheel to meet requirements of AMCA A, and AMCA B spark resistant construction. Mild steel blower wheels are of all welded construction. If higher pressure is required wheel can be furnished of high strenght steel. Stainless steel blower wheel in 304 SS, 316 SS, 316 SS, 2205 SS are supplied for corrosive applications, or high temeparature applications. The pressure curve remains stable at the top are of the fan curve and to the right of the pick point.

Inlet flanges, outlet flanges, companion flanges: continuosly welded to match ANSI class 125/150, DIN, ISO, or custom hole pattern.

Shaft seal and low leakage blower construction: shafting is straightened to close tolerance to minimize "run-out" and ensure smooth operation. Teflon shaft seal, ceramic shaft seal and lubricated shaft seals (Buna, Teflon, Viton) are standard. Red silicone gasketing is provided for low leakage construction and for high temperature construction. Heavy-duty spherical roller bearings are standard.

Heat fan construction up to 800 F: includes high temperature paint, shaft cooler, shaft-cooler guard, and steel wheel, or alloy wheel.

Cladding for sound attenuation and silencers: cladding consists of 2 inches mineral-wool insulation covered with a welded steel jacket. As an inexpensive alternative is offered slide-on acoustic cloth jackets. Inlet silencer/outlet silencer are supplied with matching flanges for further attenuation of the noise level.

Inlet filter assemblies: cell type, 1 inch, or 2 inch filters are available with filter cabinet to be mounted at fan inlet. Bird guard, insect screen and weather hood are optional accessories with inlet filter package.

Standard accessories: flash / raised access door,

inspection

port, drain and plug, unitary base, shaft and bearing guard, belt

guard,

motor cover, spring vibration isolation, rubber-in-share (RIS)

vibration

isolation, vibrating pads, outlet damper, inlet vane damper, external

inlet

vane damper, evase, electrical / pneumatic actuators.